Notizie correlate

Non ci sono notizie correlate.

University of Naples

ITA | ENG

Project

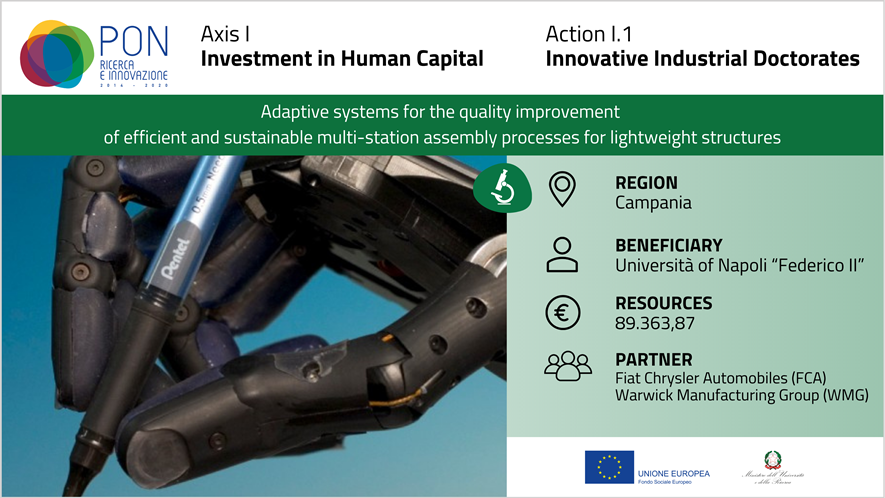

“Adaptive systems for the quality improvement of efficient and sustainable multi-station assembly processes for lightweight structures” is in line with the fourth industrial revolution, known as “Industry 4.0”. The project focuses on the energy and environmental sustainability of the automotive manufacturing industry, which is forced to find, through innovation and technology research, innovative solutions that may help address resource scarcity and increase in waste as well as producing lightweight vehicles to reduce consumption. The research aims to improve the “right-first-time” paradigm which involves a minimum waste of materials and resources, including time, energy sources and workforce.

Financial Resources

This research project was funded by the NOP Research and Innovation 2014-2020 under the action Innovative Industrial Doctorates, cycle XXXII (Academic Year 2016-2017). For the implementation of this initiative, the University of Naples “Federico II”, the beneficiary of 89.363,87 euro in funding, has instituted a 3-year doctoral scholarship in Industrial Engineering at the Industrial Engineering Department.

Impact

The project is in line with the thematic area “Smart and Sustainable Industry, Energy and Environment” of the NSSS. Evolutionary and adaptive manufacturing and assembly processes play a key role in smart and sustainable production, being far less energy-intensive and polluting and more flexible than conventional processes for the production of complex geometry mechanical components. The project includes a 6-month period at Fiat Chrysler Automobiles (FCA) and a 6-month period at Warwick Manufacturing Group WMG in the United Kingdom. The project meets the needs for flexibility and sustainability of the highly competitive Italian production system. Thanks to the interaction between Academy and large companies, the project can potentially train a professional figure that combines advanced university education, focused on the multi-station assembly of lightweight structures, and the mastery of content, methodologies and know-how of one of the most important and well-established companies in our country. These methodologies will find application in the automotive industry but, given to their centrality and cross-sectoral nature, they may also be transferred to many other companies of the Italian production system.

20/04/2021